Create a Perfect Mobility Experience

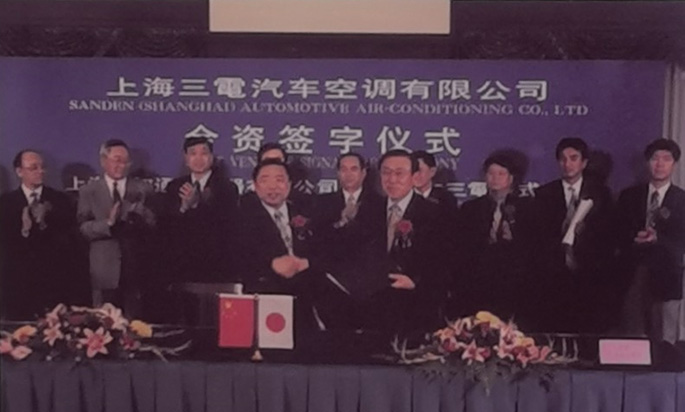

Sanden HASCO Automotive Air-Conditioning Co., Ltd. (hereinafter referred to as Sanden HASCO) is a Sino-Japanese automotive components joint venture under Huayu Automotive Systems Company Limited (HASCO). Headquartered in Shanghai, Sanden HASCO specializes in the R&D, production, and sales of automotive air-conditioning compressors and integrated thermal management systems. With a professional R&D and manufacturing team, taking the advanced technologies of Sanden Corporation as the base, while integrating global resources and making continuous independent innovations, Sanden HASCO supplies products to both New Energy Vehicles (NEVs) and Internal Combustion Engine Vehicles (ICEVs), and has built the capability of conducting synchronous development with OEMs.

As a brand holding a leading position in the industry, Sanden HASCO is the mainstream choice for numerous OEMs. We take “lead the green development of the automotive thermal management technologies, and create a perfect mobility experience for users” as our mission, and strive to become a world-class provider of automotive thermal management system solutions.

-

120million units

Cumulative Production of Compressors

-

25years

CNAS Accreditation Experience

-

30+

Countries and Regions to Which Products are Exported

-

140+

Supported Auto Production Bases

-

Our Customers are Located in These Cities

-

Our Customers are Located in These Countries

Domestic

International

-

Vision

Become a world-class provider of automotive thermal management system solutions

-

Mission

Lead the green development of the automotive thermal management technologies, and create a perfect mobility experience for users

-

Core Values

Integrity, Responsibility, Collaboration, Innovation, Enterprise, Aspiration

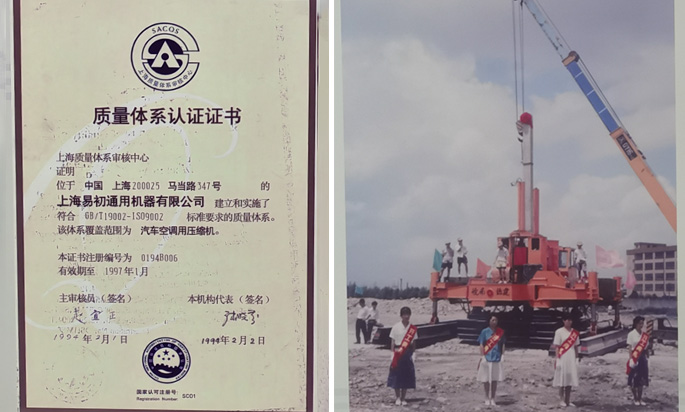

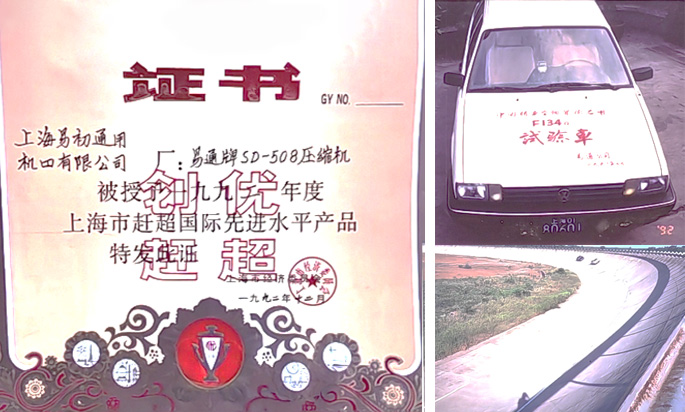

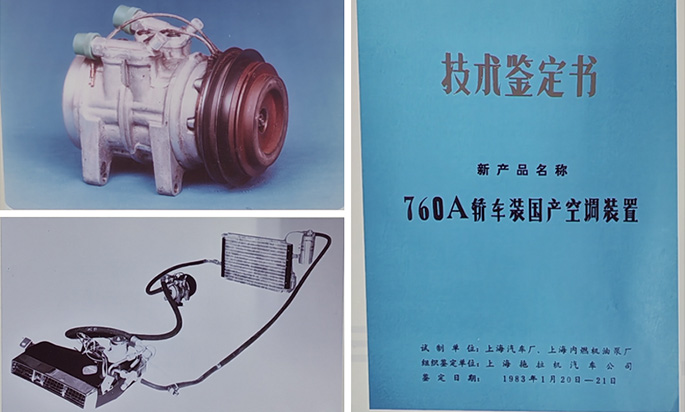

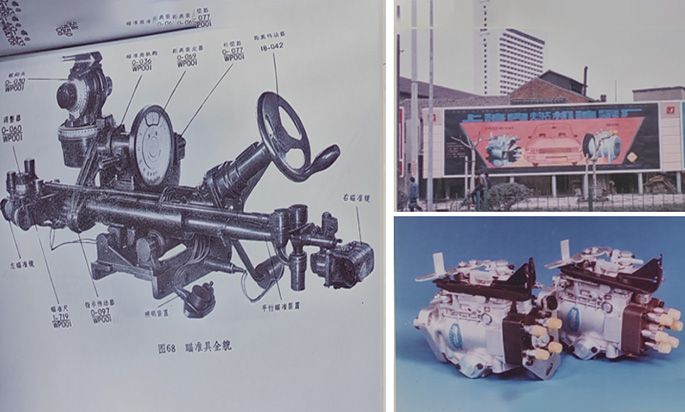

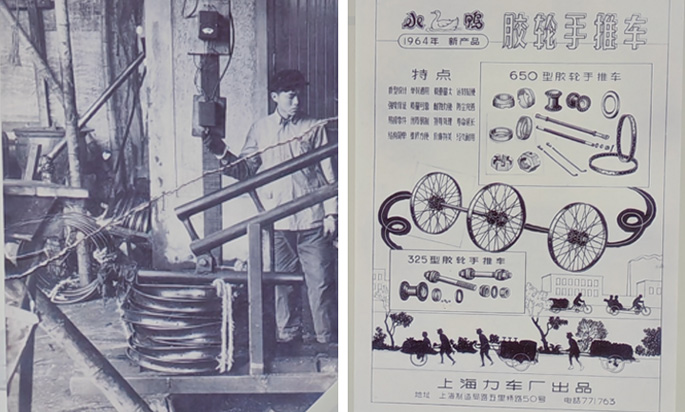

History

Honors and Awards